Table Of Content

- Production Validation Test (PVT)

- A/B Testing

- Advantages of Design Validation and Verification

- How Priority Designs Used Greenlight Guru to Gain ISO 13485:2016 Certification

- Design validation and verification: Testing your UX assumptions against reality

- Simplify V&V With Helix ALM

- Information & Training. Product & Process Validation.

VTI strives to maintain and inspire professional excellence while providing Validation Professional Services to Pharmaceuticals, Biotechnology, Biologics, Medical Devices and FDA/Internationally regulated industries. We have the experience, expertise, and commitment to provide the superior service required to meet all of your validation needs. Within our WebShop, a wide range of procedures, templates, checklists are available, all of them focused on regulatory topics for medical device compliance to applicable regulations. Within the webshop, a dedicated section related to cybersecurity and compliance to ISO for medical device organizations is also present. You should also communicate throughout the testing process to keep the whole team—and external stakeholders up to date and aligned. Make sure you test with a decent percentage of unknown users (definitely not your team!) who are unbiased.

Production Validation Test (PVT)

Archer's First-Generation Biochip gFET Design Validated by Joint Fabrication with a Foundry Partner - AZoNano

Archer's First-Generation Biochip gFET Design Validated by Joint Fabrication with a Foundry Partner.

Posted: Thu, 09 Nov 2023 08:00:00 GMT [source]

Usability testing is a go-to methodology for uncovering hidden issues, bugs, design problems and areas of confusion. It is the easiest way to find out how users interact with your product and what roadblocks they encounter. For example, we at Digital Silk have over 10 years of design experience and an award-winning design team. Hiring a graphic design agency will elevate the end results you receive through a blend of industry experience and creative minds. From discovery call to regular updates and post-launch feedback, we involve our clients in every step of our graphic design journeys. Starting with strategy, our graphic designers will then collaborate with you to bring your brand identity to life and drive brand recognition.

A/B Testing

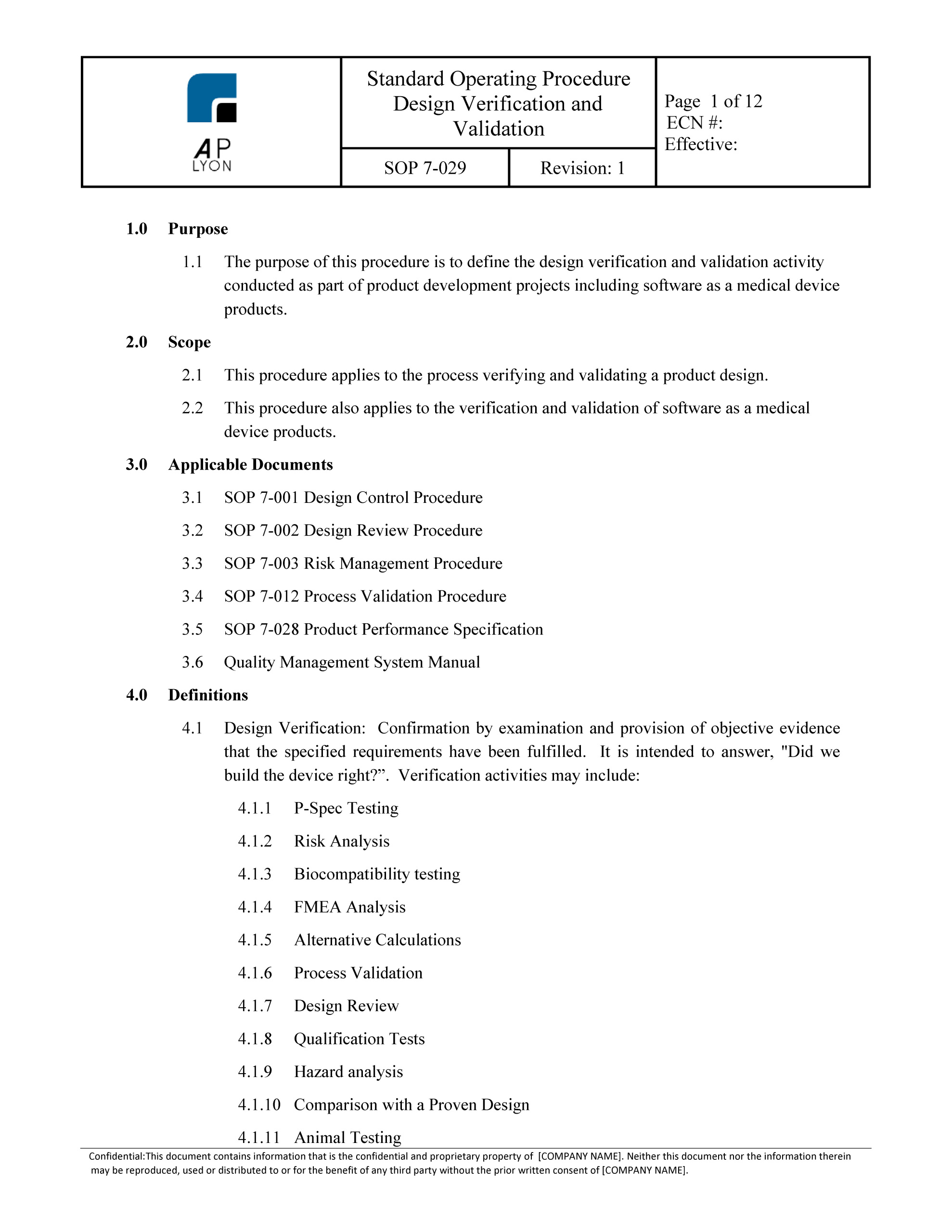

The methods play a vital role in ensuring the product meets quality and performance thresholds and is reliable. It’s worth noting that a design validation plan format varies according to an organisation’s preferences, project requirements and industry standards. But generally, a DVP format should have the essential sections and information to provide clarity and be effective. Stick to the schedule during execution and carry out the validation activities as per the defined methods.

Advantages of Design Validation and Verification

Every successful design validation plan starts with clearly defining the objectives to be achieved. It’s crucial to have a structured design validation plan template that is customised to a specific product or project. Although DVPs vary in complexity and content according to the project requirements and industry, a template has sections and guidelines for capturing essential information. So, if you’re a product development professional, what must you do to ensure that your end product meets the desired specifications? This comprehensive guide focuses on the complexities of building a Design Validation Plan that offers a procedural actionable roadmap to ensure project success. Furthermore, for clinical validation specifically, it is essential to conduct studies using representative patient populations and real-world scenarios.

These heuristics serve as principles on which your design should be based. Done correctly, these are a recipe for impeccable and validated design. Validation Package – A collection of documents produced during a validation project. Deliverable – An obligatory object produced as a result of project execution, usually documents in validation efforts. You’ll also want to consider the required resources, manpower, and tools for successful verification.

It ensures the optimal trajectory towards mass production while limiting resources to the minimum. A typical outcome of the PVT stage is 500+ units or at least 5% of the first production run quantity. The objectives are to verify mass production yields at mass production speeds and to create sellable products. This is where many companies will create a sales plan and start their operation with the early buyers.

Simplify V&V With Helix ALM

In an effort to increase user engagement in their online community, Visa enlisted the help of Khoros, a community management software, to redesign their community page. With the launch of their Visa Developer Platform in 2016, the goal was to connect external developers with the Visa Developer team through educational and support articles. However, their community page felt more like a blog and it wasn’t easy for users to navigate to the developer forum. Airbnb’s anti-discrimination team rigorously conducts discovery to uncover biases on the platform — they use that data to improve user experience. Many tech startups prioritize delivering products to market quickly because they face steep competition.

The most important part of testing is turning test insights into actions. Use Hotjar Heatmaps to visualize exactly where users are clicking and scrolling—then deploy Recordings, Feedback widgets, and Surveys to go deeper and find out why. Verification and validation are different processes with different goals that are often mixed up. So, if you’re ready to visualize the connections within your device’s design and your QMS like never before, then get your free demo of Greenlight Guru today. Also note that you need to make as few changes as possible in each version, ideally one tweak per version.

Deterministic vs. robust design optimization using DEM-based metamodels - ScienceDirect.com

Deterministic vs. robust design optimization using DEM-based metamodels.

Posted: Sat, 01 Jul 2023 07:00:00 GMT [source]

Information & Training. Product & Process Validation.

Dedication to quality, personalized support and the success of your projects are the foundation of our company. Our passion is the establishment of long-term relationships with our customers achieved by consistently providing the highest quality of service. Excellence in service is derived from the commitment, competency and dedication of our employees.

During the EVT stage, the development team aims to establish confidence that the design will function correctly. The DVT stage verifies that the design can successfully be manufactured at scale and passes a myriad of testing procedures, while PVT is there to ensure that the production line can meet the desired metrics. During mass production, the focus is on sales, maintaining quality, handling returns, preparing future design changes, and end-of-life. Validation testing is the phase-gate process of determining whether a piece of hardware meets the requirements set upon it by its stage of maturity and if it’s ready to progress to the next stage. In the process, designers and engineers build numerous kinds of prototypes.

Benchmarking partially helps overcome the retrospective analysis’ downsides we’ve mentioned. If the metrics are on par with the industry average, so is your design. Another important caveat is that you'll need 5 users per feature or a group of features. According to research conducted by Nielsen Norman Group, 5 is the optimal number of users to test your design on. The reason it's optimal is because 6 is the point of diminishing returns, while 4 and fewer users will not give you as many insights as you need.

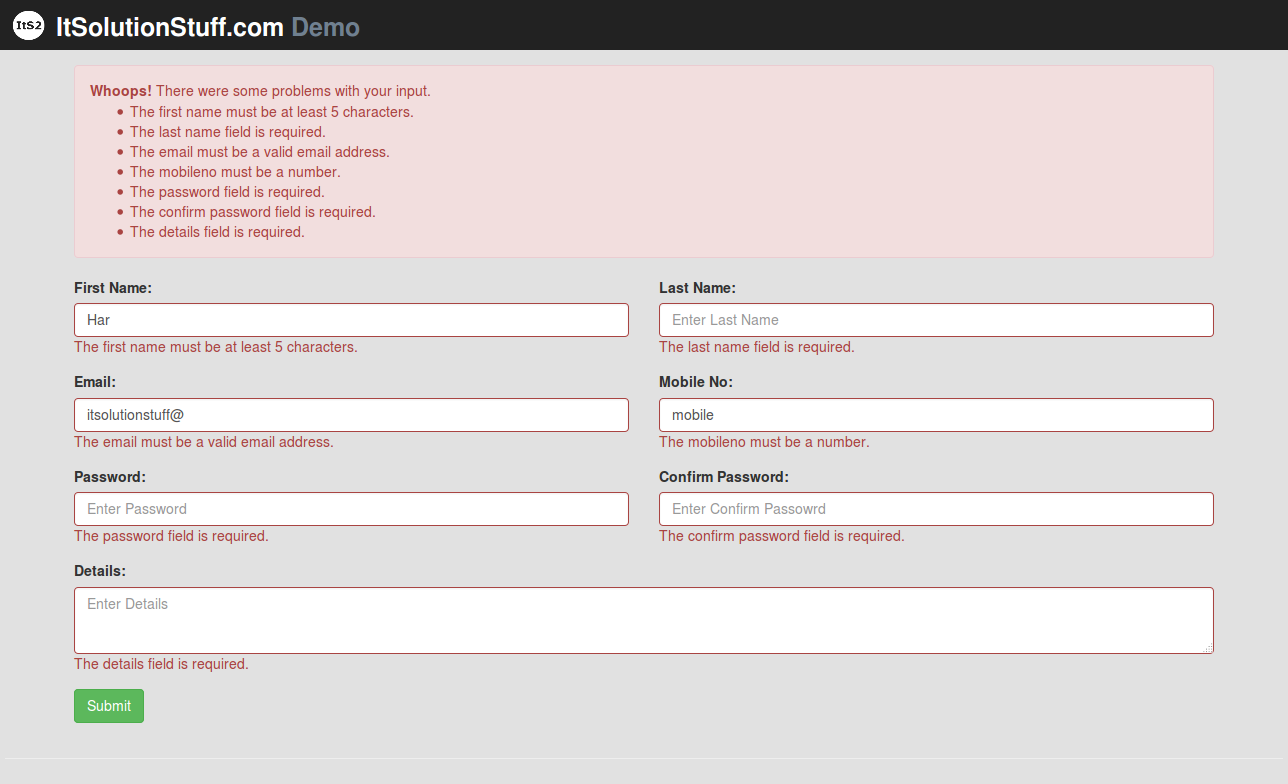

Neglecting to verify designs can lead to a higher likelihood of users encountering bugs. Verification seeks to evaluate whether designs meet the outlined requirements and user needs While validation focuses on user research, verification can be thought of as quality control and usability testing. Some of the most common methods for design validation include user research activities like interviews, surveys, or observation — you’re probably familiar with all of these. You typically employ these methods during the discovery phase of the design process, when you need a better understanding of the problem space before defining design requirements. After a thorough review, it’s time to start verification and validation again. No matter when in the product lifecycle you make the change, you can’t skip verification and validation.

If you develop products — medical devices, particularly — then you’ve heard the terms and design verification and validation (also called V&V). Here we’ll explain what the two activities are, the difference between them, plus share tips for getting the most out of your efforts. A design validation plan and report (DVP&R) is a document consisting of the tests carried out to assess the efficacy of a design to meet its requirements and specifications. In most cases, the DVP&R finds its use at the evaluation stage, however, it ought to be created after defining the design requirements. Engineers should also ensure that a DVP&R exists before embarking on the engineering of the design. The last design validation plan step is to instil a culture of continuous improvement.

To facilitate the design verification process, it is imperative to develop a comprehensive test plan for each specific requirement. These test plans outline the procedures and methodologies to be followed in order to validate and verify the design outputs. For design verification, the FDA expects manufacturers to develop and execute a comprehensive verification plan that includes specific objectives, test methods, acceptance criteria, and documentation of results.

Be specific with your user needs and avoid vague or relative language. Design verification and validation both require some foresight, and it’s essential that you create plans for each of them ahead of time. Proper preparation will help you discover and avoid potential obstacles early in the process and improve your efficiency. The result was a personalized experience that was optimized for user engagement and showcased Visa’s brand, which led to a 124 percent increase in users.

Essentially, in design verification, we need to demonstrate that the product we built is the product we said we would build. Verification of the design specifications, which we'll show next, shows that the product does it the way we said it would do it. The schedule should be realistic, factoring all potential delays and other unforeseen challenges. The best way to go about this is to discuss the plan with the stakeholders and to ensure each team’s necessities are put into consideration.

No comments:

Post a Comment